| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: HAL300 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

HAL300

Differential Hall Effect

Sensor IC

Edition July 15, 1998

6251-345-1DS

MICRONAS

MICRONAS

HAL300

2

Micronas

Differential Hall Effect Sensor IC

in CMOS technology

Introduction

The HAL 300 is a differential Hall switch produced in

CMOS technology. The sensor includes 2 temperature-

compensated Hall plates (2.05 mm apart) with active off-

set compensation, a differential amplifier with a Schmitt

trigger, and an open-drain output transistor (see Fig. 2).

The HAL 300 is a differential sensor which responds to

spatial differences of the magnetic field. The Hall volt-

ages at the two Hall plates, S

1

and S

2

, are amplified with

a differential amplifier. The differential signal is

compared with the actual switching level of the internal

Schmitt trigger. Accordingly, the output transistor is

switched on or off.

The sensor has a bipolar switching behavior and re-

quires positive and negative values of

B = B

S1

≠ B

S2

for

correct operation.

The HAL 300 is an ideal sensor for applications with a ro-

tating multi-pole-ring in front of the branded side of the

package (see Fig. 4 and Fig. 5), such as ignition timing,

anti-lock brake systems, and revolution counting.

For applications in which a magnet is mounted on the

back side of the package (back-biased applications), the

HAL 320 is recommended.

The active offset compensation leads to constant mag-

netic characteristics over supply voltage and tempera-

ture.

The sensor is designed for industrial and automotive ap-

plications and operates with supply voltages from 4.5 V

to 24 V in the ambient temperature range from ≠40

∞

C

up to 150

∞

C.

The HAL 300 is available in a SMD-package (SOT-89A)

and in a leaded version (TO-92UA).

Features:

≠ distance between Hall plates: 2.05 mm

≠ operates from 4.5 V to 24 V supply voltage

≠ switching offset compensation at 62 kHz

≠ overvoltage protection

≠ reverse-voltage protection at V

DD

-pin

≠ short-circuit protected open-drain output by thermal

shutdown

≠ operates with magnetic fields from DC to 10 kHz

≠ output turns low with magnetic south pole on branded

side of package and with a higher magnetic flux densi-

ty in sensitive area S1 as in S2

≠ on-chip temperature compensation circuitry mini-

mizes shifts of the magnetic parameters over temper-

ature and supply voltage range

≠ the decrease of magnetic flux density caused by rising

temperature in the sensor system is compensated by

a built-in negative temperature coefficient of hystere-

sis

≠ EMC corresponding to DIN 40839

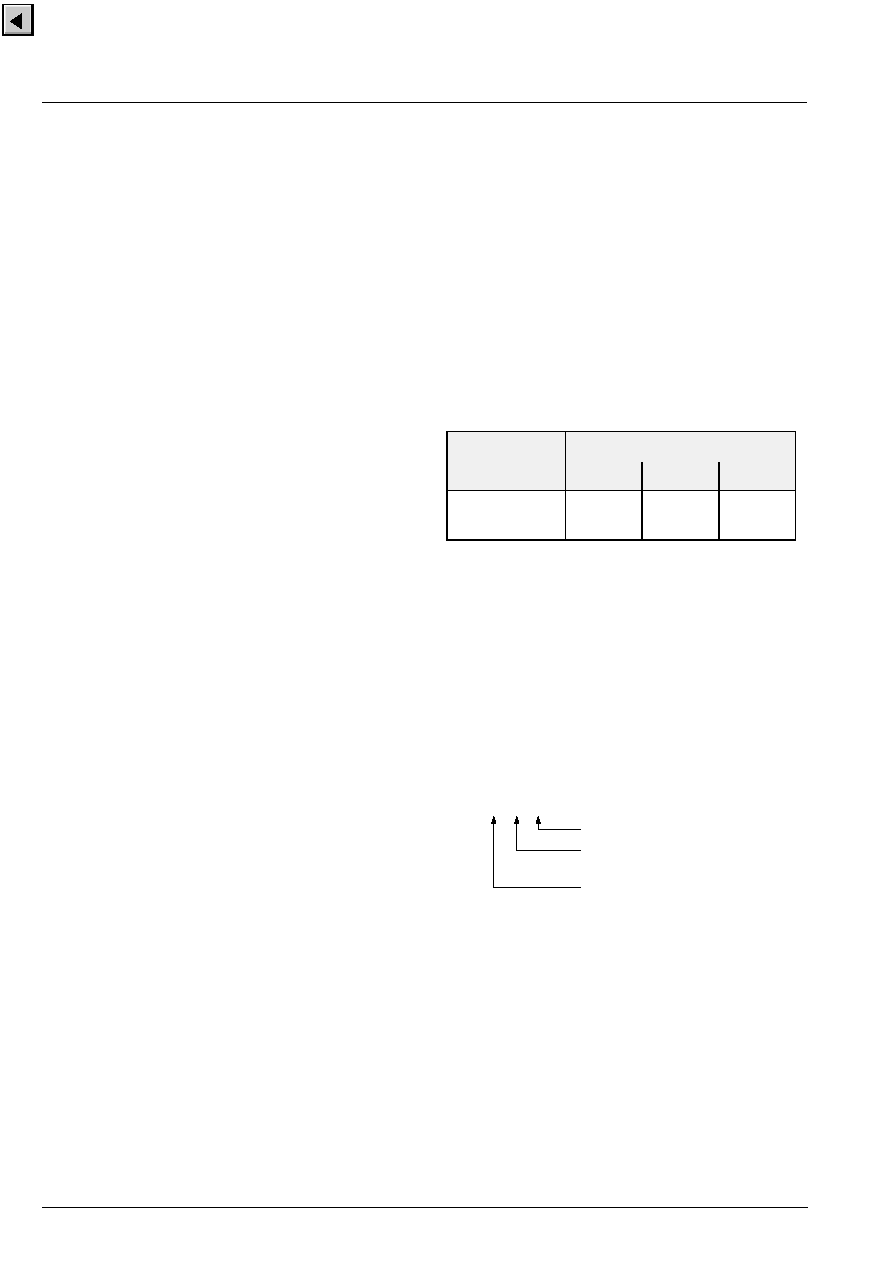

Marking Code

Type

Temperature Range

A

E

C

HAL 300SO,

HAL 300UA

300A

300E

300C

Operating Junction Temperature Range (T

J

)

A: T

J

= ≠40

∞

C to +170

∞

C

E: T

J

= ≠40

∞

C to +100

∞

C

C: T

J

= 0

∞

C to +100

∞

C

The relationship between ambient temperature (T

A

) and

junction temperature (T

J

) is explained on page 11.

Hall Sensor Package Codes

Type: 300

HAL XXXPA-T

Temperature Range: A, E, or C

Package: SO for SOT-89A,

UA for TO-92UA

Type: 300

Package: TO-92UA

Temperature Range: T

J

= ≠40

∞

C to +100

∞

C

Example: HAL 300UA-E

Hall sensors are available in a wide variety of packaging

versions and quantities. For more detailed information,

please refer to the brochure: "Ordering Codes for Hall

Sensors".

HAL300

3

Micronas

Solderability

≠ Package SOT-89A: according to IEC68-2-58

≠ Package TO-92UA: according to IEC68-2-20

OUT

GND

3

2

1

V

DD

Fig. 1: Pin configuration

Functional Description

This Hall effect sensor is a monolithic integrated circuit

with 2 Hall plates 2.05 mm apart that switches in

response to differential magnetic fields. If magnetic

fields with flux lines at right angles to the sensitive areas

are applied to the sensor, the biased Hall plates force

Hall voltages proportional to these fields. The difference

of the Hall voltages is compared with the actual thresh-

old level in the comparator. The temperature-dependent

bias increases the supply voltage of the Hall plates and

adjusts the switching points to the decreasing induction

of magnets at higher temperatures. If the differential

magnetic field exceeds the threshold levels, the open

drain output switches to the appropriate state. The built-

in hysteresis eliminates oscillation and provides

switching behavior of the output without oscillation.

Magnetic offset caused by mechanical stress at the Hall

plates is compensated for by using the "switching offset

compensation technique": An internal oscillator pro-

vides a two phase clock (see Fig. 3). The difference of

the Hall voltages is sampled at the end of the first phase.

At the end of the second phase, both sampled differen-

tial Hall voltages are averaged and compared with the

actual switching point. Subsequently, the open drain

output switches to the appropriate state. The amount of

time that elapses from crossing the magnetic switch lev-

el to the actual switching of the output can vary between

zero and 1/f

osc

.

Shunt protection devices clamp voltage peaks at the

Output-Pin and V

DD

-Pin together with external series

resistors. Reverse current is limited at the V

DD

-Pin by an

internal series resistor up to ≠15 V. No external reverse

protection diode is needed at the V

DD

-Pin for values

ranging from 0 V to ≠15 V.

HAL 300

Temperature

Dependent

Bias

Switch

Hysteresis

Control

Comparator

Output

V

DD

1

OUT

3

Clock

GND

2

Fig. 2: HAL 300 block diagram

Short Circuit &

Overvoltage

Protection

Reverse

Voltage &

Overvoltage

Protection

Hall Plate

S1

Hall Plate

S2

t

V

OL

V

OUT

1/f

osc

= 16

µ

s

Fig. 3: Timing diagram

V

OH

D

B

D

B

ON

f

osc

t

t

t

f

t

I

DD

t

HAL300

4

Micronas

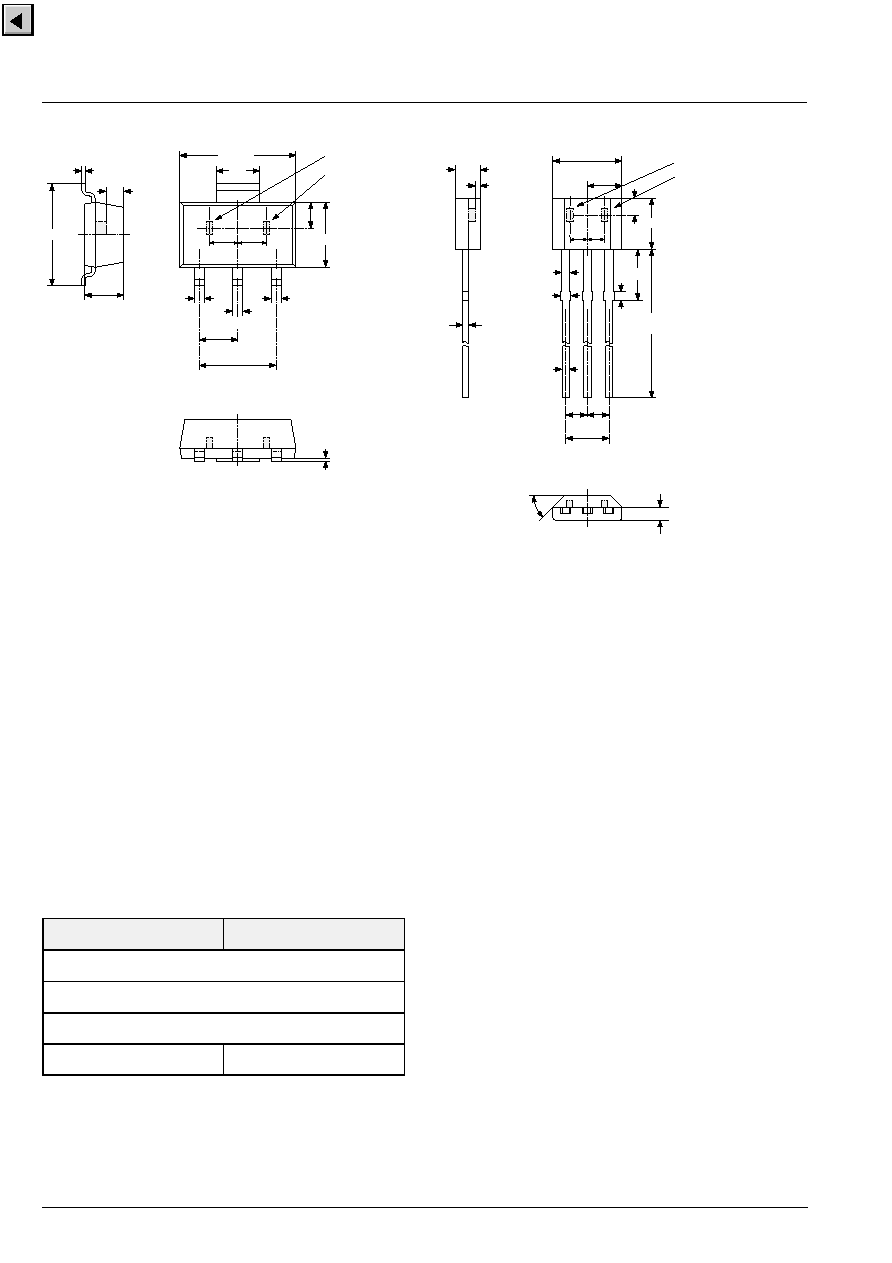

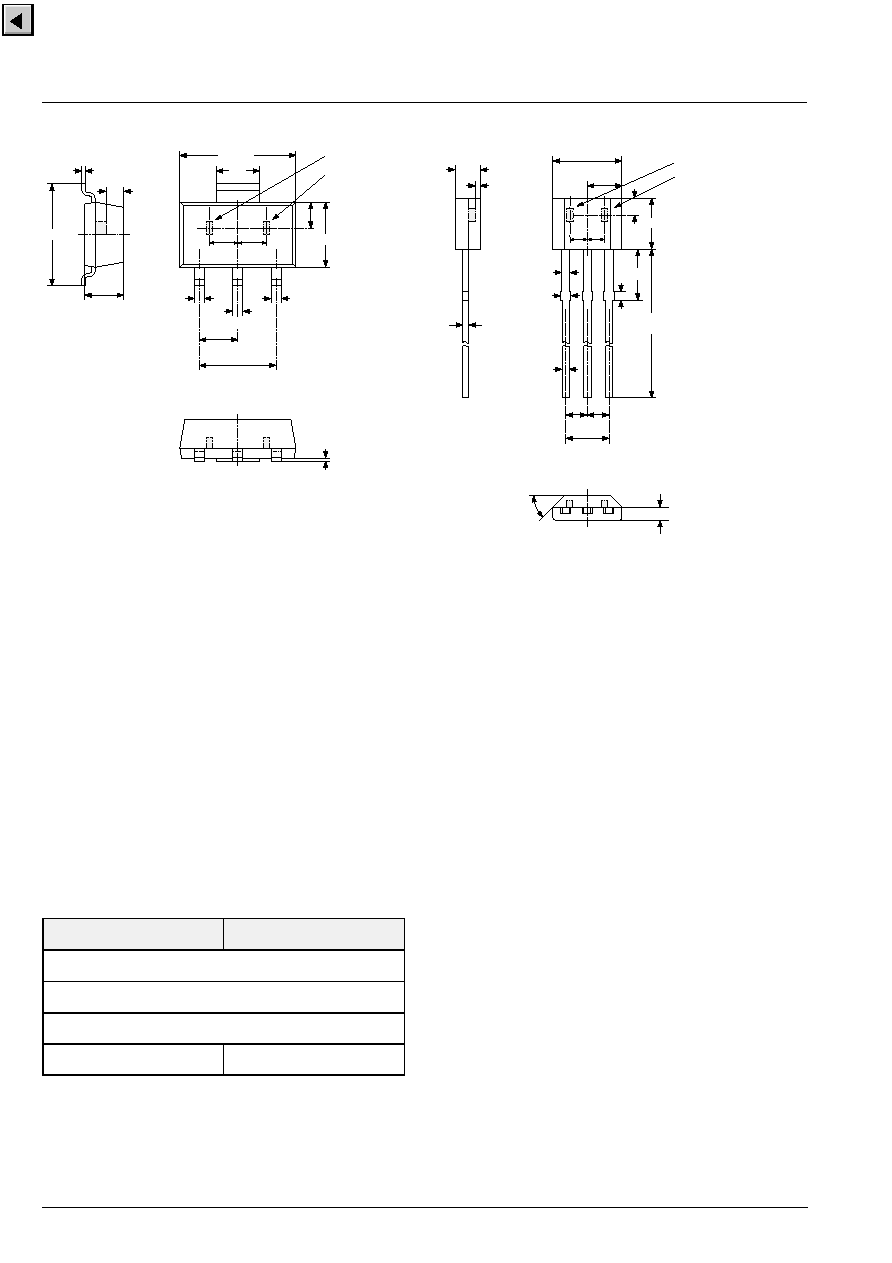

Outline Dimensions

Fig. 4:

Plastic Small Outline Transistor Package

(SOT-89A)

Weight approximately 0.04 g

Dimensions in mm

4.55

±

0.1

2.6

±

0.1

0.4

0.4

1.7

0.4

1.5

3.0

0.06

±

0.04

4

±

0.2

1.53

±

0.05

0.125

SPGS7001-6-B3/1E

top view

y

1

2

3

2

0.7

sensitive area S

1

sensitive area S

2

x

1

x

2

branded side

Dimensions of Sensitive Areas

0.08 mm x 0.17 mm

Positions of Sensitive Areas

SOT-89A

TO-92UA

x

1

= ≠1.025 mm

±

0.2 mm

x

2

= 1.025 mm

±

0.2 mm

x

2

≠ x

1

= 2.05 mm

±

0.01 mm

y = 0.98 mm

±

0.2 mm

y = 1.0 mm

±

0.2 mm

x

1

and x

2

are referenced to the center of the package

0.55

branded side

0.36

0.8

0.3

45

∞

y

14.0

min.

3.1

1.27

1.27

2.54

1

2

3

0.5

0.42

Fig. 5:

Plastic Transistor Single Outline Package

(TO-92UA)

Weight approximately 0.12 g

Dimensions in mm

1.5

±

0.05

4.06

±

0.1

2.03

3.05

±

0.1

0.48

sensitive area S

1

sensitive area S

2

SPGS7002-6-B/1E

x

1

x

2

HAL300

5

Micronas

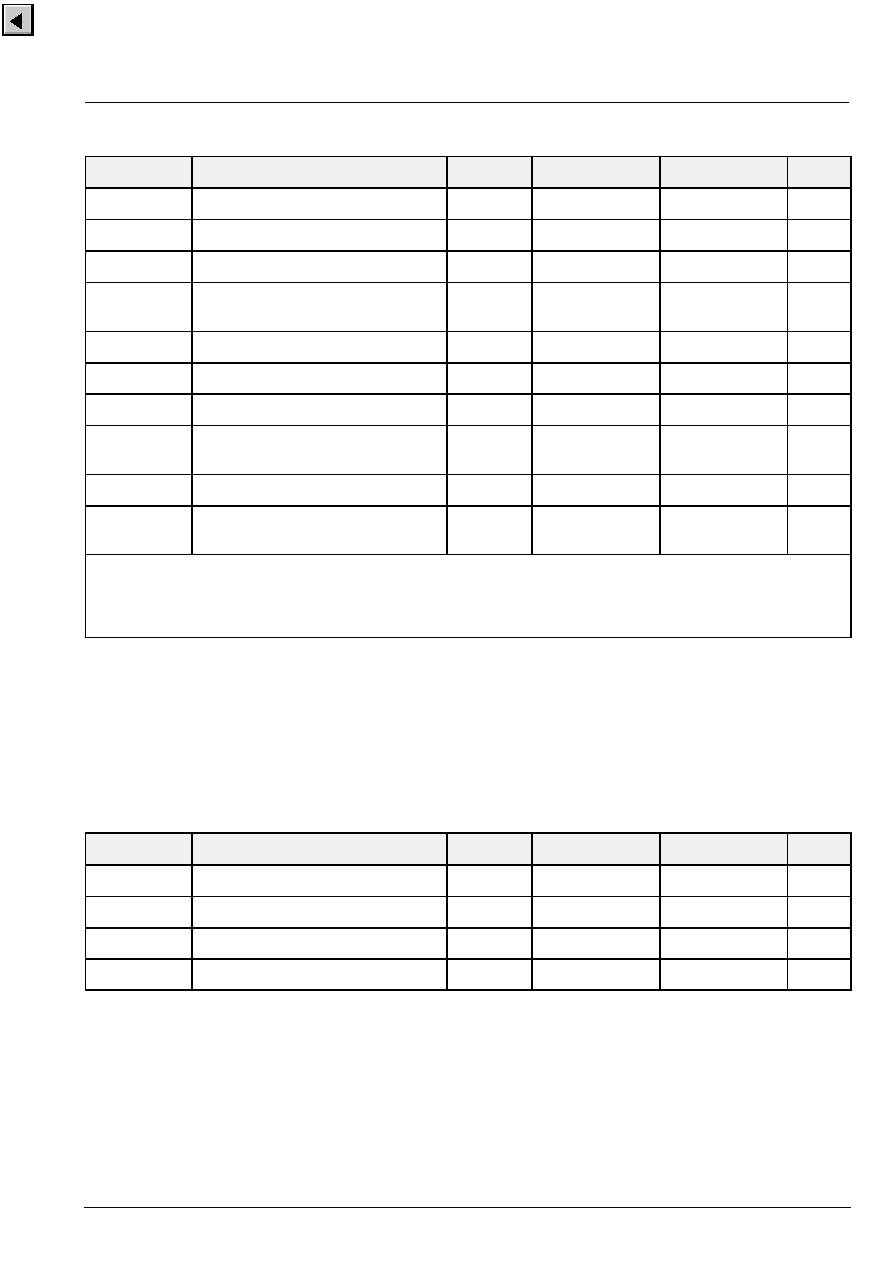

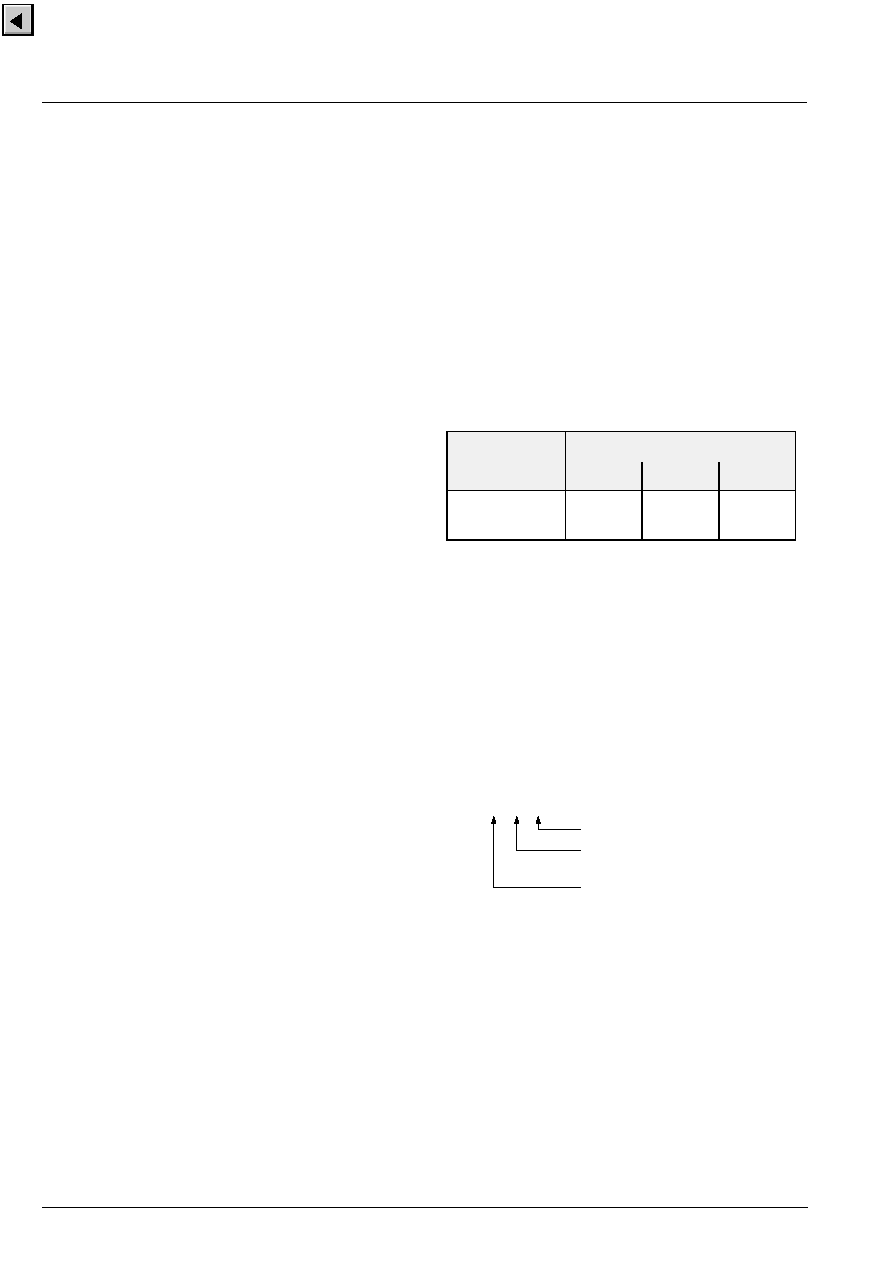

Absolute Maximum Ratings

Symbol

Parameter

Pin No.

Min.

Max.

Unit

V

DD

Supply Voltage

1

≠15

28

1)

V

≠V

P

Test Voltage for Supply

1

≠24

2)

≠

V

≠I

DD

Reverse Supply Current

1

≠

50

1)

mA

I

DDZ

Supply Current through

Protection Device

1

≠200

3)

200

3)

mA

V

O

Output Voltage

3

≠0.3

28

1)

V

I

O

Continuous Output On Current

3

≠

30

mA

I

Omax

Peak Output On Current

3

≠

250

3)

mA

I

OZ

Output Current through

Protection Device

3

≠200

3)

200

3)

mA

T

S

Storage Temperature Range

≠65

150

∞

C

T

J

Junction Temperature Range

≠40

≠40

150

170

4)

∞

C

1)

as long as T

J

max

is not exceeded

2)

with a 220

series resistance at pin 1 corresponding to test circuit 1

3)

t < 2 ms

4)

t < 1000h

Stresses beyond those listed in the "Absolute Maximum Ratings" may cause permanent damage to the device. This

is a stress rating only. Functional operation of the device at these or any other conditions beyond those indicated in the

"Recommended Operating Conditions/Characteristics" of this specification is not implied. Exposure to absolute maxi-

mum ratings conditions for extended periods may affect device reliability.

Recommended Operating Conditions

Symbol

Parameter

Pin No.

Min.

Max.

Unit

V

DD

Supply Voltage

1

4.5

24

V

I

O

Continuous Output On Current

3

≠

20

mA

V

O

Output Voltage

3

≠

24

V

R

v

Series Resistor

1

≠

270

HAL300

6

Micronas

Electrical Characteristics at T

J

= ≠40

∞

C to +170

∞

C , V

DD

= 4.5 V to 24 V, as not otherwise specified in Conditions

Typical Characteristics for T

J

= 25

∞

C and V

DD

= 12 V

Symbol

Parameter

Pin No.

Min.

Typ.

Max.

Unit

Conditions

I

DD

Supply Current

1

4.0

5.5

6.8

mA

T

J

= 25

∞

C

I

DD

Supply Current over

Temperature Range

1

2.5

5

7.5

mA

V

DDZ

Overvoltage Protection

at Supply

1

≠

28.5

32.5

V

I

DD

= 25 mA, T

J

= 25

∞

C,

t = 20 ms

V

OZ

Overvoltage Protection at Output

3

≠

28

32.5

V

I

OL

= 25 mA, T

J

= 25

∞

C,

t = 20 ms

V

OL

Output Voltage

3

≠

180

250

mV

V

DD

= 12 V, I

O

= 20 mA,

T

J

= 25

∞

C

V

OL

Output Voltage over

Temperature Range

3

≠

180

400

mV

I

O

= 20 mA

I

OH

Output Leakage Current

3

≠

0.06

1

µ

A

V

OH

= 4.5 V... 24 V,

D

B <

D

B

OFF

, T

J

= 25

∞

C

I

OH

Output Leakage Current over

Temperature Range

3

≠

0.06

10

µ

A

V

OH

= 4.5 V... 24 V,

D

B <

D

B

OFF

, T

J

150

∞

C

f

osc

Internal Oscillator

Chopper Frequency

≠

42

62

75

kHz

T

J

= 25

∞

C

f

osc

Internal Oscillator Chopper Fre-

quency over Temperature Range

≠

36

62

78

kHz

t

en(O)

Enable Time of Output

after Setting of V

DD

3

≠

35

≠

µ

s

V

DD

= 12 V,

D

B >

D

B

ON

+ 2mT or

D

B <

D

B

OFF

≠ 2mT

t

r

Output Rise Time

3

≠

80

400

ns

V

DD

= 12 V, RL = 820

,

CL = 20 pF

t

f

Output Fall Time

3

≠

45

400

ns

V

DD

= 12 V, RL = 820

,

CL = 20 pF

R

thJSB

case

SOT-89A

Thermal Resistance Junction to

Substrate Backside

≠

150

200

K/W

Fiberglass Substrate

30 mm x 10 mm x 1.5mm,

pad size see Fig. 7

R

thJS

case

TO-92UA

Thermal Resistance

Junction to Soldering Point

≠

150

200

K/W

HAL300

7

Micronas

Magnetic Characteristics at T

J

= ≠40

∞

C to +170

∞

C, V

DD

= 4.5 V to 24 V

Typical Characteristics for V

DD

= 12 V

Magnetic flux density values of switching points (Condition: ≠10 mT < B

0

< 10 mT)

Positive flux density values refer to the magnetic south pole at the branded side ot the package.

B = B

S1

≠ B

S2

Parameter

≠40

∞

C

25

∞

C

100

∞

C

170

∞

C

Unit

Min.

Typ.

Max.

Min.

Typ.

Max.

Min.

Typ.

Max.

Min.

Typ.

Max.

On point

B

ON

B >

B

ON

0.2

1.2

2.2

0

1.2

2.2

≠0.5

1.0

2.5

≠2.0

0.5

3.0

mT

Off point

B

OFF

B <

B

OFF

≠2.2

≠1.0

≠0.2

≠2.2

≠1.0

0

≠2.5

≠1.1

0.5

≠3.0

≠1.2

2.0

mT

Hysteresis

B

HYS

=

B

ON

≠

B

OFF

1.2

2.2

3.0

1.2

2.2

3.0

1.0

2.1

3.0

0.8

1.7

3.0

mT

Offset

B

OFFSET

=

(

B

ON

+

B

OFF

)/2

≠1.1

0.1

1.1

≠1.1

0.1

1.1

≠1.5

≠0.1

1.5

≠2.5

≠0.5

2.5

mT

D

B

OFF min

D

B

ON max

D

B

HYS

Output Voltage

Fig. 6: Definition of switching points and hysteresis

0

D

B

OFF

D

B

ON

B = B

S1

≠ B

S2

V

OH

V

OL

Fig. 7: Recommended pad size SOT-89A

Dimensions in mm

5.0

2.0

2.0

1.0

HAL300

8

Micronas

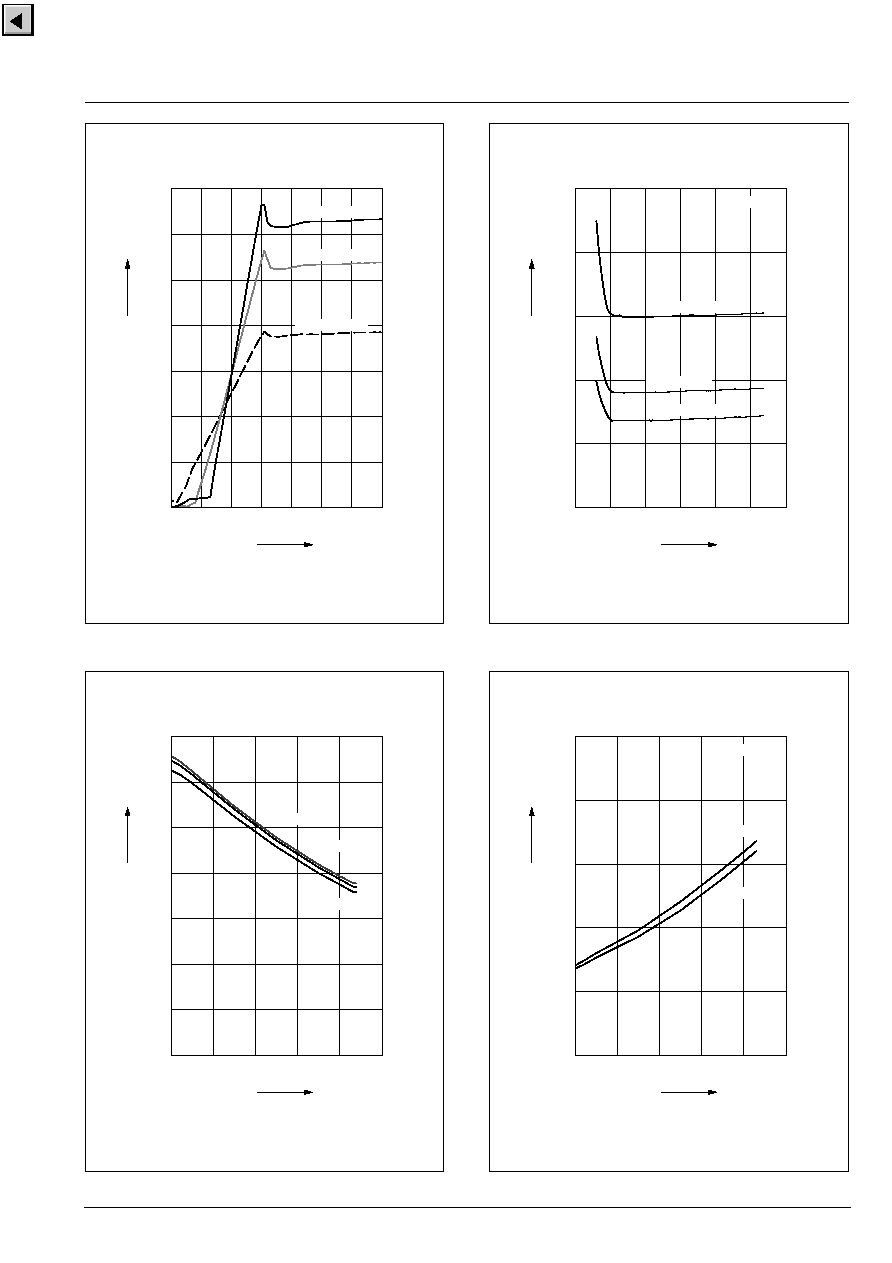

≠2.5

≠2.0

≠1.5

≠1.0

≠0.5

0.0

0.5

1.0

1.5

2.0

2.5

0

5

10

15

20

25

30

mT

V

DD

V

D

B

ON

D

B

OFF

T

A

= 25

∞

C

T

A

= ≠40

∞

C

T

A

= 150

∞

C

D

B

ON

D

B

OFF

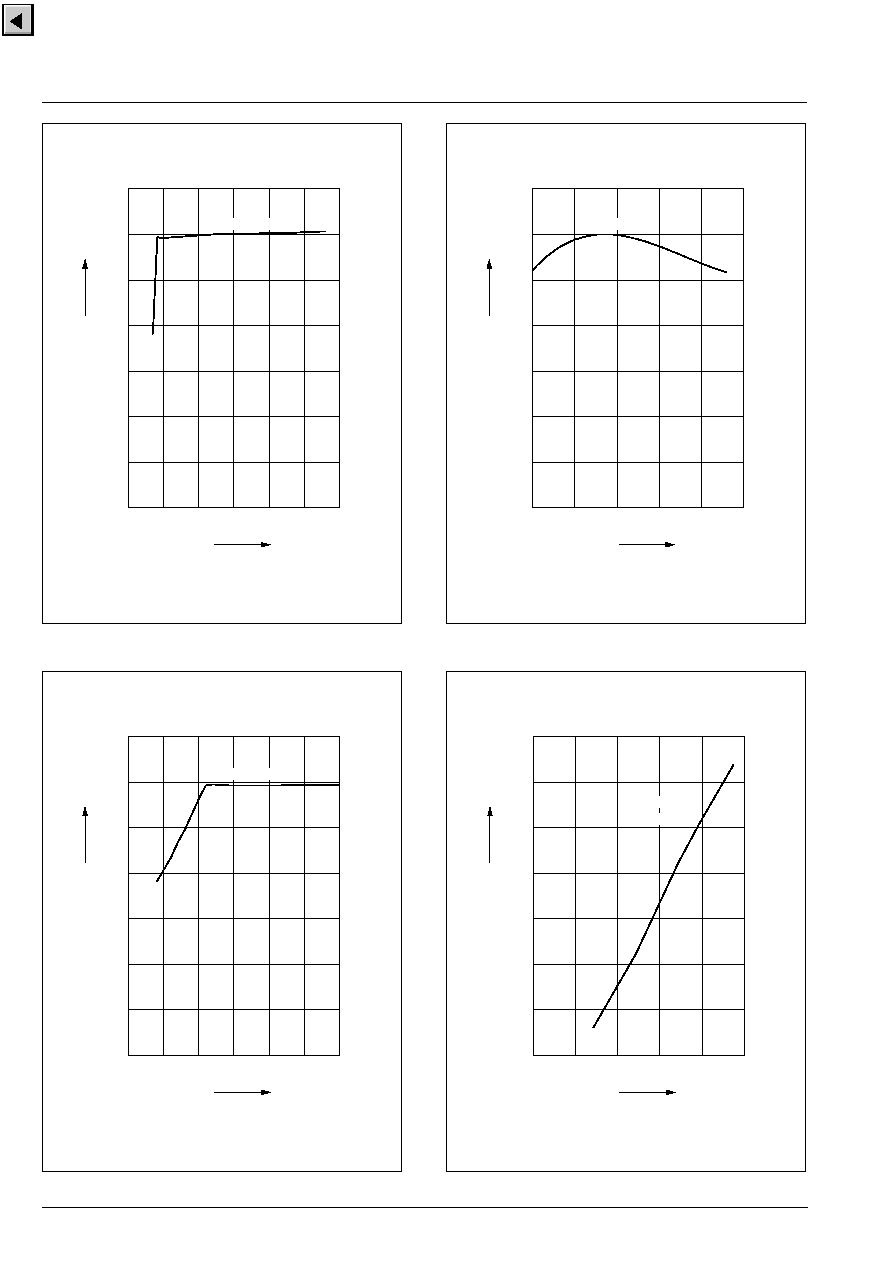

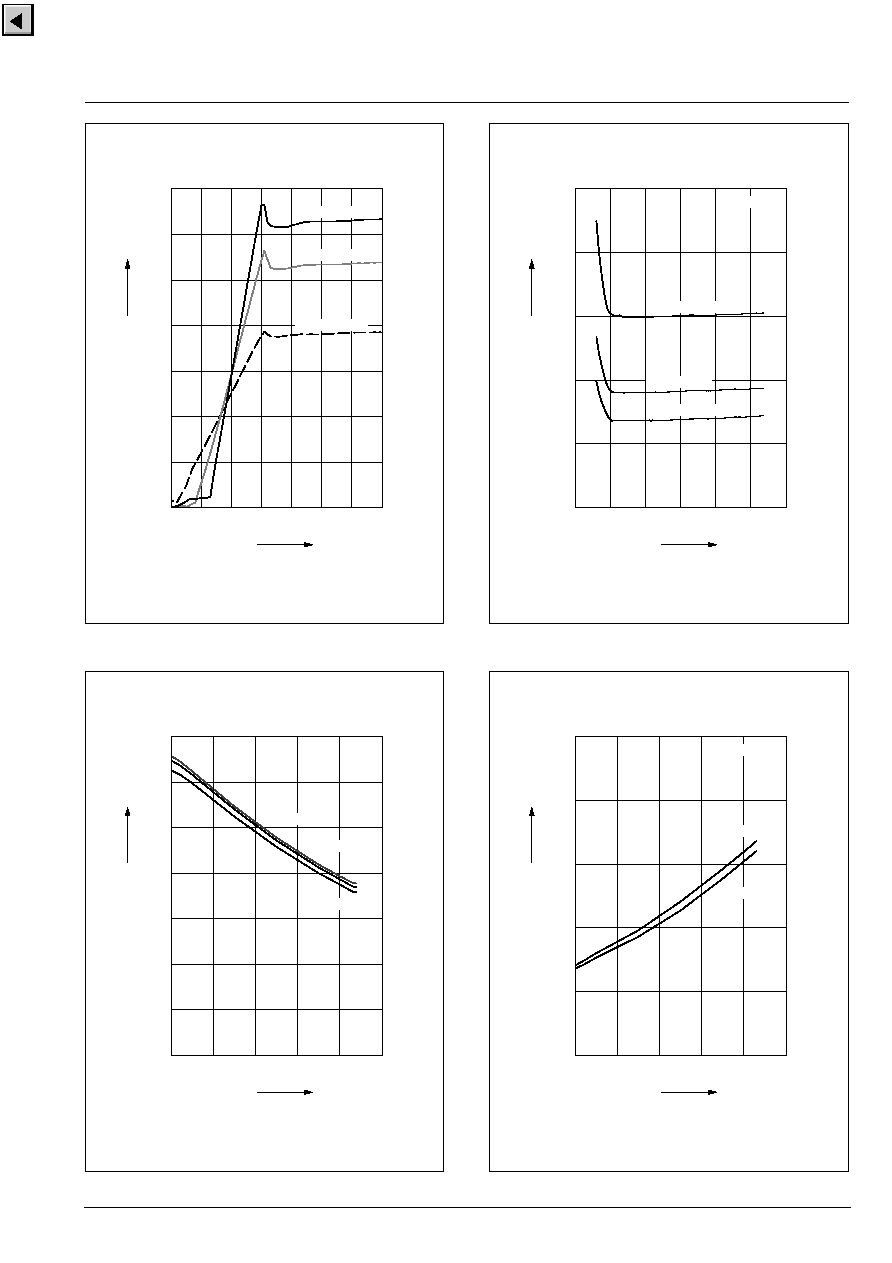

Fig. 8: Typical magnetic switch points

versus supply voltage

≠2.5

≠2.0

≠1.5

≠1.0

≠0.5

0.0

0.5

1.0

1.5

2.0

2.5

3

3.5

4.0

4.5

5.0

5.5

6.0

mT

V

DD

V

D

B

ON

D

B

OFF

D

B

ON

D

B

OFF

T

A

= 25

∞

C

T

A

= ≠40

∞

C

T

A

= 150

∞

C

Fig. 9: Typical magnetic switch points

versus supply voltage

≠2.5

≠2.0

≠1.5

≠1.0

≠0.5

0.0

0.5

1.0

1.5

2.0

2.5

≠50

0

50

100

150

200

mT

T

A

∞

C

D

B

ON

D

B

OFF

V

DD

= 4.5 V

D

B

ON

D

B

OFF

V

DD

= 12 V

V

DD

= 24 V

Fig. 10: Typical magnetic switch points

versus ambient temperature

≠15

≠10

≠5

0

5

10

15

20

≠15 ≠10 ≠5

0

5

10 15 20 25 30 V

mA

V

DD

I

DD

25

T

A

= 25

∞

C

T

A

= ≠40

∞

C

T

A

= 150

∞

C

Fig. 11: Typical supply current

versus supply voltage

HAL300

9

Micronas

0

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8 V

mA

V

DD

I

DD

T

A

= ≠40

∞

C

T

A

= 25

∞

C

T

A

= 150

∞

C

Fig. 12: Typical supply current

versus supply voltage

0

1

2

3

4

5

6

7

≠50

0

50

100

150

200

∞

C

mA

T

A

I

DD

V

DD

= 24 V

V

DD

= 12 V

V

DD

= 4.5 V

Fig. 13: Typical supply current

versus ambient temperature

0

100

200

300

400

500

0

5

10

15

20

25

30 V

mV

V

DD

V

OL

T

A

= 150

∞

C

T

A

= 25

∞

C

T

A

= ≠40

∞

C

Fig. 14: Typical output low voltage

versus supply voltage

I

O

= 20 mA

0

100

200

300

400

500

≠50

0

50

100

150

200

∞

C

mV

T

A

V

OL

V

DD

= 24 V

V

DD

= 4.5 V

Fig. 15: Typical output low voltage

versus ambient temperature

I

O

= 20 mA

HAL300

10

Micronas

0

10

20

30

40

50

60

70

0

5

10

15

20

25

30 V

kHz

V

DD

f

osc

T

A

= 25

∞

C

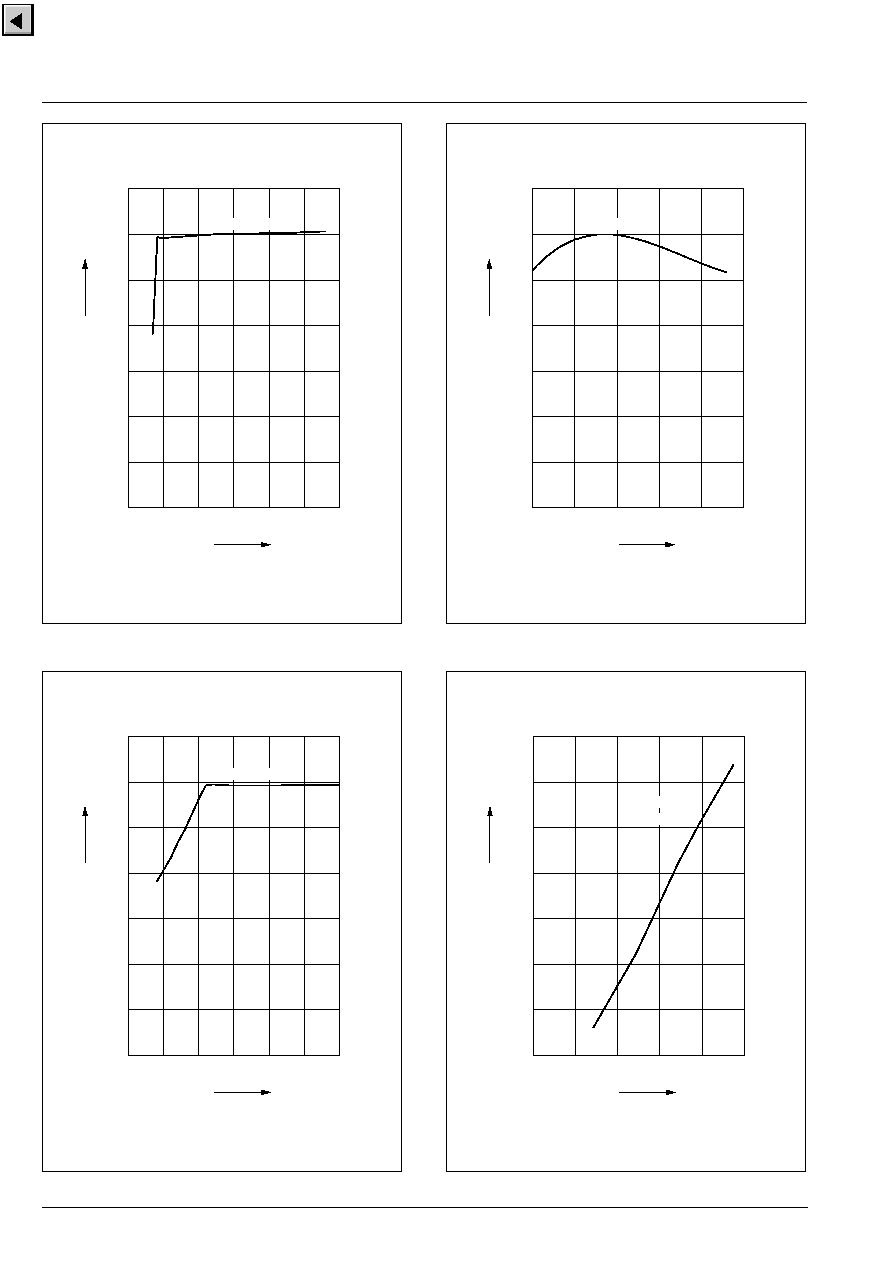

Fig. 16: Typical internal chopper frequency

versus supply voltage

0

10

20

30

40

50

60

70

3

3.5

4.0

4.5

5.0

5.5

6.0 V

kHz

V

DD

f

osc

T

A

= 25

∞

C

Fig. 17: Typical internal chopper frequency

versus supply voltage

0

10

20

30

40

50

60

70

≠50

0

50

100

150

200

kHz

T

A

f

osc

V

DD

= 12 V

∞

C

Fig. 18: Typical internal chopper frequency

versus ambient temperature

≠50

0

50

100

150

200

µ

A

T

A

I

OH

∞

C

10

0

10

≠1

10

≠2

10

≠3

10

≠4

10

≠5

10

1

10

2

V

OH

= 24 V

V

DD

= 5 V

Fig. 19: Typical output leakage current

versus ambient temperature

HAL300

11

Micronas

20

22

24

26

28

30

µ

A

V

OH

I

OH

V

10

0

10

≠1

10

≠2

10

≠3

10

≠4

10

≠5

10

1

10

2

V

DD

= 5 V

T

A

= 125

∞

C

T

A

= 75

∞

C

T

A

= 25

∞

C

Fig. 20: Typical output leakage current

versus output voltage

Application Notes

Mechanical stress can change the sensitivity of the Hall

plates and an offset of the magnetic switching points

may result. External mechanical stress to the package

can influence the magnetic parameters if the sensor is

used under back-biased applications. This piezo sensi-

tivity of the sensor IC cannot be completely compen-

sated for by the switching offset compensation tech-

nique.

For back-biased applications, the HAL 320 is recom-

mended. In such cases, please contact our Application

Department. They will provide assistance in avoiding

applications which may induce stress to the ICs. This

stress may cause drifts of the magnetic parameters indi-

cated in this data sheet.

For electromagnetic immunity, it is recommended to ap-

ply a 4.7 nF capacitor between V

DD

(pin 1) and Ground

(pin 2). For automotive applications, a 220

W

series re-

sistor to pin 1 is recommended. Because of the I

DD

peak

at 4.1 V, the series resistor should not be greater than

270

. The series resistor and the capacitor should be

placed as close as possible to the IC.

Ambient Temperature

Due to the internal power dissipation, the temperature

on the silicon chip (junction temperature T

J

) is higher

than the temperature outside the package (ambient tem-

perature T

A

).

T

J

= T

A

+

T

At static conditions, the following equations are valid:

≠ for SOT-89A:

T = I

DD

* V

DD

* R

thJSB

≠ for TO-92UA:

T = I

DD

* V

DD

* R

thJA

For typical values, use the typical parameters. For worst

case calculation, use the max. parameters for I

DD

and

R

th

, and the max. value for V

DD

from the application.

Test Circuits for Electromagnetic Compatibility

Test pulses V

EMC

corresponding to DIN 40839.

OUT

GND

3

2

1

V

DD

4.7 nF

V

EMC

V

P

R

V

220

R

L

1.2 k

20 pF

Fig. 21: Test circuit 2: test procedure for class A

OUT

GND

3

2

1

V

DD

4.7 nF

V

EMC

R

V

220

R

L

680

Fig. 22: Test circuit 1: test procedure for class C

HAL300

12

Micronas

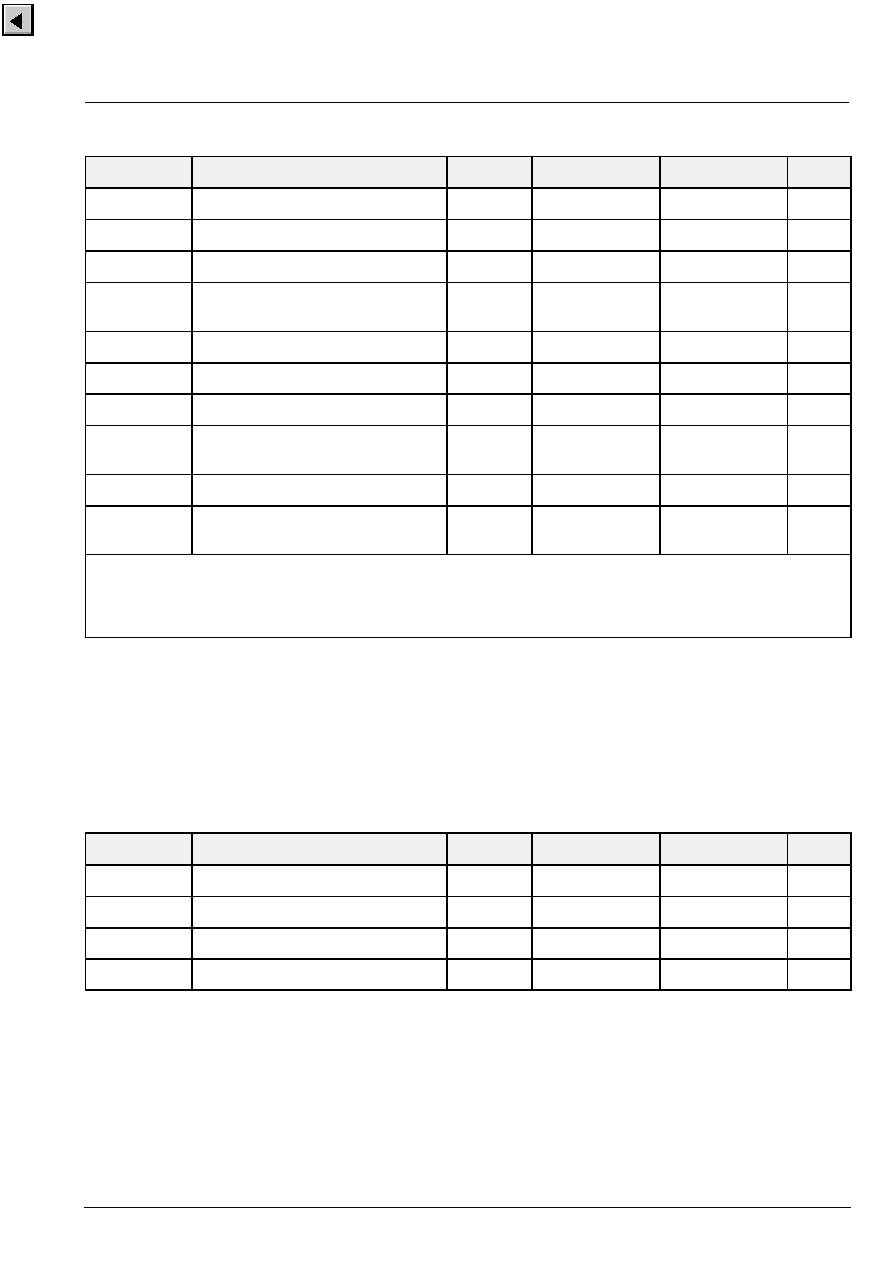

Interferences conducted along supply lines in 12 V onboard systems

Product standard: DIN 40839 part 1

Pulse

Level

U

s

in V

Test

circuit

Pulses/

Time

Function

Class

Remarks

1

IV

≠100

1

5000

C

5 s pulse interval

2

IV

100

1

5000

C

0.5 s pulse interval

3a

IV

≠150

2

1 h

A

3b

IV

100

2

1h

A

4

IV

≠7

2

5

A

5

IV

86.5

1

10

C

10 s pulse interval

Electrical transient transmission by capacitive and inductive coupling via lines other than the supply lines

Product standard: DIN 40839 part 3

Pulse

Level

U

s

in V

Test

circuit

Pulses/

Time

Function

Class

Remarks

1

IV

≠30

2

500

A

5 s pulse interval

2

IV

30

2

500

A

0.5 s pulse interval

3a

IV

≠60

2

10 min

A

3b

IV

40

2

10 min

A

Radiated Disturbances

Product standard: DIN 40839 part 4

Test Conditions

≠ Temperature:

Room temperature (22 ... 25

∞

C)

≠ Supply voltage:

13 V

≠ Lab equipment:

TEM cell 220 MHz (VW standard)

with adaptor board 455 mm, device 80 mm over ground

≠ Frequency range: 5 ... 220 MHz; 1 MHz steps

≠ Test circuit 2 with R

L

= 1.2 k

Tested Devices and Results

Type

Field

strength

Modulation

Result

HAL 300

> 200 V/m

1 kHz 80 %

output voltage stable on the level high or low

1)

1)

low level

t

0.4 V, high level

u

90% of V

DD

HAL300

13

Micronas

HAL300

14

Micronas

HAL300

15

Micronas

HAL300

16

Micronas

Data Sheet History

1. Final data sheet: "HAL 300 Differential Hall Effect

Sensor IC", July 15, 1998, 6251-345-1DS. First release

of the final data sheet.

Micronas GmbH

Hans-Bunte-Strasse 19

D-79108 Freiburg (Germany)

P.O. Box 840

D-79008 Freiburg (Germany)

Tel. +49-761-517-0

Fax +49-761-517-2174

E-mail: docservice@micronas.com

Internet: www.micronas.com

Printed in Germany

by Systemdruck+Verlags-GmbH, Freiburg (07/1998)

Order No. 6251-345-1DS

All information and data contained in this data sheet are without any

commitment, are not to be considered as an offer for conclusion of a

contract, nor shall they be construed as to create any liability. Any new

issue of this data sheet invalidates previous issues. Product availability

and delivery are exclusively subject to our respective order confirma-

tion form; the same applies to orders based on development samples

delivered. By this publication, Micronas GmbH does not assume re-

sponsibility for patent infringements or other rights of third parties

which may result from its use.

Further, Micronas GmbH reserves the right to revise this publication

and to make changes to its content, at any time, without obligation to

notify any person or entity of such revisions or changes.

No part of this publication may be reproduced, photocopied, stored on

a retrieval system, or transmitted without the express written consent

of Micronas GmbH.

Micronas

page 1 of 1

Subject:

Data Sheet Concerned:

Supplement:

Edition:

Data Sheet Supplement

Changes:

≠ position tolerance of the sensitive area reduced

≠ tolerances of the outline dimensions reduced

≠ thickness of the leadframe changed to 0.15 mm (old 0.125 mm)

≠ HAL 300 now available in SOT-89B

≠ SOT-89A will be discontinued in December 2000

Position of sensitive area

Note: A mechanical tolerance of

±

0.05 mm applies to all dimensions where no tolerance is explicitly given.

Position tolerances of the sensitive areas are defined in the package diagram.

HAL 300

HAL 320

x

1

+x

2

(2.05

±

0.001) mm

(2.25

±

0.001) mm

x

1

= x

2

1.025 mm nominal

1.125 mm nominal

y

0.95 mm nominal

0.95 mm nominal

sensitive area S

1

4.55

min.

0.25

x

1

x

2

2.55

0.4

0.4

1.7

0.4

1.5

3.0

0.06

±

0.04

4

±

0.2

0.15

branded side

SPGS0022-5-B3/1E

top view

y

1

2

3

2

0.3

1.15

0.2

sensitive area S

2

0.2

Improvement of SOT-89B Package

HAL 300, 6251-345-1DS, Edition July 15, 1998

HAL 320, 6251-439-1DS, Edition July 15, 1998

No. 1/ 6251-532-1DSS

July 4, 2000

HAL 300, HAL 320